The natural environment

Height: 2000m

Environment temperature: -5 ℃ -+50 ℃

Relative humidity: ≤ 90% (20 ± 5 ℃)

Non conductive and explosive dust, non corrosive gas

No violent vibration and impact

The use of indoor and ventilated

System parameters

Precision: within 0.5%

Current stabilizing precision: within 0.5%

Ripple factor: ≤ ± 0.1%

Power factor: = 0.92

Efficiency: = 94%

Noise: ≤ 45Db

Current sharing Unbalance: ≤ 3%

The reliability index: MTBF = 100000h

AC input voltage range: 380V ± 15%

The AC voltage frequency range: 50HZ ± 10%

Scope of application

Power 'M is functional integration of DC power supply system in our company is suitable for DC system of 200Ah and below, can be installed 4 K4810 (K4A20) module, which can provide 220V / 40A (110V / 80A).

System features

● used to form 200Ah and DC system below, for, small transformer substation. Can be installed up to 4 K4810 (K4A20) module, which can provide 220V / 40A{110V / 80A).

● rectifier module maximum configuration module for 1 control female power.

● module and monitoring unit adopts electric plug structure, installation, convenient maintenance.

● module and monitoring unit in a bracket, compact structure.

● monitoring has been completed parenting voltage, voltage controlled current controlling mother, mother, battery charging and discharging current detection, no external sensing.

The monitoring unit has a level 5 or 7 grade silicon chain pressure automatic control function, only with the silicon chain can realize the control of parent automatic voltage regulator.

The monitoring unit adopts LCD display, Chinese characters menu, key operation, can realize the system parameter setting, parameter display, system fault indicator and system calibration.

The monitoring unit has the function of automatic management of battery.

The monitoring unit provides RS232 / RS485 communication interface, built-in CDT and ModbuS two communication protocol, can be connected with the power plant automation system.

Technical parameters of the system

AC input: AC380V ± 20% grid frequency: 50Hz ± 10%

Power factor: ≥ 0.92 input over-voltage protection: 380 ± 20%

Precision: ≤ ± 0.5% current stabilizing precision: within 0.5%

Efficiency: ≥ 94% ripple coefficient: ≤ 0.1%

Insulation resistance: = 10M Ω audible noise: ≤ 55dB

Environment temperature: -5 ℃ ~+45 ℃, relative humidity: ≤ 90% (20 ± 5 ℃)

Dielectric strength: 2KVAC minutes without flashover, no breakdown

Output voltage: 180V~270V set (220V system)

90V~135V set (110V system)

Output current: 20A~40A (220V system with 2-4 rectifier module)

40A~80A (110V system with 2-4 rectifier module)

Battery capacity: 65Ah~200Ah (220V system)

100Ah~300Ah (110V system)

Battery charging management: automatic

Battery temperature compensation: batteries inspection can be realized

Body size: 800 x 600 x 2260 or 800 x 600 x 2360

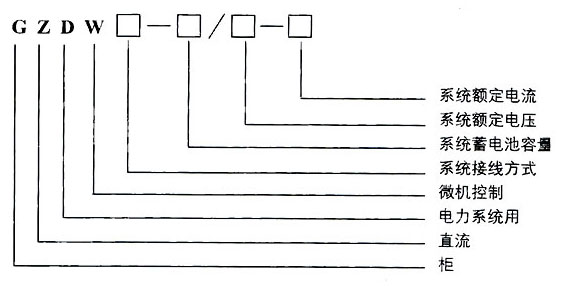

The system wiring scheme: GZDW33 and GZDW35

System options

|

The selection of equipment

|

Scheme selection

|

Program description

|

|

The main control unit of PS2 system

|

Will accessories

|

This scheme suitable for DC system of 200Ah and below, single bus not segment for, single group battery system; can configure 1 module is used to control the master power supply. Many feeder output system can feed cabinet configuration independent.

|

|

K4B10 (K4A20) rectifier module

|

||

|

The feeder output

|

||

|

Charging cabinet

|

||

|

Battery cabinet

|

||

|

PM3A communication control unit

|

Optional accessories

|

|

|

PM2J/PM3J insulation monitoring unit

|

||

|

PM2B battery checking unit

|

||

|

KD2B10 (KD2A15) reducing module

|

||

|

Buck silicon chain

|